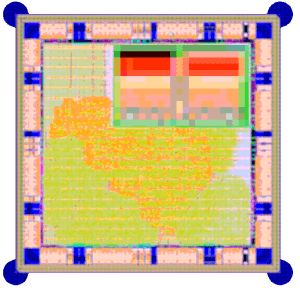

An ASIC – Application Specific Integrated Circuit – is an integrated circuit specifically tailored to your application.

By embedding your electronic subsystem into an ASIC, you will boost performance and save board space while protecting your intellectual property by making reverse engineering almost impractical.

Today, even companies with small to medium volumes can leverage the benefits of custom ASICs to add differentiated features to their products.

Already developed your ASIC prototype?

We support you turning it into an industrial circuit and ramp up its production.

Experienced with integrated electronics but need some support with your design?

The a-la-carte model is made for you.

Reduced BoM (Bill of Materials)

Smaller PCB

Reduced product weight & size

First-time right project execution

Traceability of projects

On-time delivery

Reliability of the supply chain

Less external components (active & passif)

Better power management control

Lower power consumption

Full system integration

Intellectual property & know-how protected

New functionalities

Optimization of performances

Specific regulatory compliance

Dedicated supply chain Full chip ownership Complete independence in techologies choice

With IC’Alps as partner, you are starting in the right place. We have an in-house pool of experts for system architecture, design, physical implementation, project management, and supply management.

For each ASIC project, we set up the team of specialists to develop jointly your exclusive, on target and cost effective custom Integrated Circuit. What you just have to do is to focus on your expertise and applications!

As a prime contractor, we can complement your team or provide end-to-end ASIC solutions from your concept, specifying the architecture for your ASIC, through circuit design, silicon, production and ASIC supply across diverse applications.

Are you considering using an ASIC for your application but don’t know how to start?

During this first stage in the design process, we understand your application and system constraints to create in close cooperation with you a turnkey and preliminary ASIC architecture that complies with your technical, economical and time related requirements.

How does it work? We dedicate a team for your project, to provide you within a 1 to 3 months timeframe, a la carte report:

Translating your custom needs into an exclusive ASIC layout

The ASIC design step includes:

Our projects generally combine in-house analog and digital blocks and some third party IPs Standard cells & IO, interfaces, power management, PLL/DLL, ADC/DAC, memory, MCU…to ensure

To guarantee first-time-right ASIC solutions, our high-quality design and supply processes are built around ISO 9001:2015 Quality Management System. Beyond our standard design workflow, we can apply specific guidelines and requirements to design and supply ISO 13485:2016 compliant ASICs for medical devices or EN 9100:2018 compliant ASICs for aeronautics, space and defence applications. IC’Alps’ Grenoble site is also Common Criteria certified (with isolated network, dedicated server, secured access, encryption and data traceability).

Full support beyond GDSII to characterize state of art ASICs at our measurement lab facility and validate the specification

At this stage, we focus on ASIC prototype manufacturing:

We make your prototype ready for volume manufacturing

The industrialization phase includes:

We set up and manage the complete supply chain for your ASIC

As your prime contractor we organize your whole production flow from silicon manufacture through to test and life cycle management. Our independence and experience ensure that we can identify and select the best supply chain partners to fit with your performance, cost and timescale requirements.

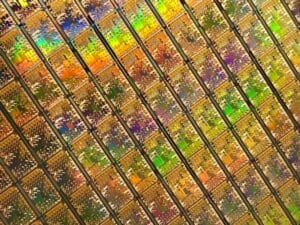

With a privileged access to world-class foundries and technologies, we can offer affordable prices for ASICs manufacturing even for small batches through MPW (Multi Project Wafer) service where ASICs from different customers are combined for production.

Custom Integrated Circuits are at the heart of innovations in Healthcare, Industrial applications, IoT, Automotive and Aeronautics, Space & Defence. These are just a few of the growing number of applications for ASICs.

We have established partnerships with key industry providers to get access to the best EDA tools, IP, technology, manufacturing asset and packaging process available on the market.

Our partnerships in these areas enable us to offer the optimum end-to-end ASIC solution for each customer.