Because it is cheaper (and always safer) to prevent rather than correct or assume failure consequences, the Failure Modes and Effects Analysis (FMEA) method is implemented to detect, correct and prevent risks of systematic failure as early as possible.

And because ASICs are often at the heart if critical system functions in many applications, IC’Alps incorporates the FMEA as a cornerstone of its development strategy for Automotive in compliance with IATF 16949 standard and other safety sensitive applications: healthcare or aeronautics. This proactive risk assessment tool helps avoid systematic failures, ensures high-quality, dependable products. In addition, incorporating this method directly support customer aiming for ISO 26262 certification as well as ASIL-A to D designs.

You will find in this article a definition of FMEA, a focus on Design FMEA (DFMEA) and how it translates to our ASIC Design process at IC’Alps.

What is FMEA in Automotive?

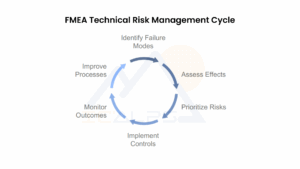

FMEA stands for Failure Mode and Effects Analysis. It is a critical method in technical risk management, distinct from other tools that handle project risks like finances, timelines, or strategies.

FMEA is a requirement for products developed under the IATF 16949 standard. Its primary goal is to anticipate and prevent risks in design and production, ensuring robust product quality that encompasses yield, reliability, and safety.

Key Objectives and Benefits

- Preventive Action for Quality: FMEA identifies risks early, enabling preventive measures that improve overall quality.

- Challenging Murphy’s Law: It systematically addresses « what can go wrong, » minimizing surprises during development.

- Improved Outcomes:

- Enhanced customer satisfaction

- Cost savings from avoiding rework and failures

- Reduced development cycle times

- Continuous improvements in product and process quality

How does FMEA translates for ASIC Design?

FMEA can be categorized into two main types, depending on the focus area: Design FMEA (DFMEA) and Process FMEA (PFMEA). DFMEA is the first one handled at IC’Alps while the PFMEA, targeting the manufacturing, assembly and logistics processes is driven with the concerned partners.

Why DFMEA for ASIC Design?

Many significant advantages can be found in integrating DFMEA in ASIC design over other types of solutions. Already tailored to the final Automotive application, ASIC benefits from DFMEA by:

- Prevent ASIC malfunction: failure risks are identified earlier in development

- DFMEA helps reduce development costs by adressing potential issues before the first silicon even exit the foundry

- DFMEA streamlines verification and validation process. It ensures smoother certification thanks to a faster regulatory approval due to a structured risk analysis approach

- Minimize performance degradation or loss of product performance

- Automotive ASICs designed with DFMEA have predictable failure modes, allowing for proactive risk mitigation

The 7 steps process of DFMEA

In 2019, an harmonization of AIAG (Automotive Industry Action Group) and VDA (Verband der Automobilindustrie) standards occured in order to facilitate, improve the methodology and control the Cost of Quality. Based on the best practices from this two standards, DFMEA was transformed into a 7-steps structure approach.

DFMEA in Action at IC’Alps

As a design&supply house specializing, among other fields, in the Automotive industry, IC’Alps has fully integrated DFMEA requirements and methodology and adapted them to its activities.

A distinctive feature of IC’Alps is the extension of DFMEA usage, initially designed to meet the needs of the automotive industry, to other applications where safety is a critical factor, such as healthcare and aeronautics.

Comprehensive Scope

Our take on DFMEA covers not only the design flow itself but also all the later stages as it must cover:

- All functions of the ASIC: analog, digital or mixed, including Design for Test

- The assembly/packaging

- All technical risks related to Design, already identified as risk for the project development

- Product Safety special characteristics, identified by the customer or during Functional Safety Analysis

- Customer identified special characteristics

- Points of attention related to design, highlighted by the customer

Integration with Project Development

IC’Alps embeds DFMEA into its project lifecycle, ensuring that design, verification, and manufacturing processes are risk-aware. From identifying high-risk areas like ESD (Electrostatic Discharge) and EMC (Electromagnetic compatibility) resilience to documenting lessons from past designs, DFMEA serves as a critical feedback loop.

Collaborative Effort

DFMEA requires a cross-functional team, involving members from all relevant disciplines. The structure includes:

- Core Team: Responsible for preparing, executing, and reviewing DFMEA.

- Extended Team: Experts consulted for specific areas as needed.

- Management: Ensures process effectiveness, compliance, and promotes risk-based thinking.

Continuous Improvement

- Updating DFMEA with insights from bugs, audits, and RMAs (Reliability, Maintainability, and Availability) ensures the process evolves with each project.

- Risk decisions are systematically tracked, fostering accountability and clarity.

The tools of DFMEA in ASIC Development

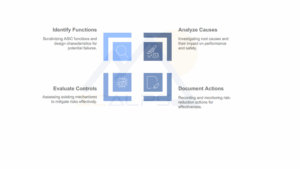

- Identify Functions and Failure Modes: Every function of the ASIC—whether analog, digital, or mixed-signal—is scrutinized, including aspects like Design for Test (DFT) and assembly/packaging. Customer-specified design characteristics and functional safety analysis outcomes are also evaluated.

- Analyze Causes and Effects: The DFMEA team delves into root causes of potential failures, examining their impact on performance, safety, and reliability.

- Evaluate Controls: Existing prevention and detection mechanisms are assessed to ensure they adequately mitigate risks. If risks remain high, the team recommends additional actions.

- Document and Track Actions: All risk-reduction actions are meticulously documented and monitored to ensure their effectiveness.

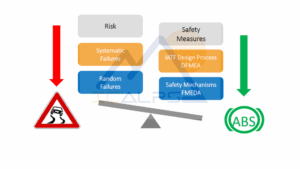

It is worth noting that, while DFMEA methodolgy aims at adressing systematic failures (failures resulting from design, process, or human errors), it complements with the ISO 26262 standard (FMEDA –Failure Modes, Effects, and Diagnostic coverage Analysis) that aims at adressing random failures.

DFMEA empowers IC’Alps to anticipate and mitigate risks, ensuring robust ASIC designs that meet stringent quality and safety standards. By fostering collaboration, leveraging lessons learned, and focusing on proactive risk management, DFMEA transforms potential challenges into opportunities for innovation and reliability.

At IC’Alps, DFMEA is a framework that drives excellence in ASIC design. Through its structured approach, the DFMEA process ensures that every aspect of design is scrutinized, tested, and optimized for success.

Bertrand Clou

Toulouse Design Center Manager